Hesaglas

technical

possibilities

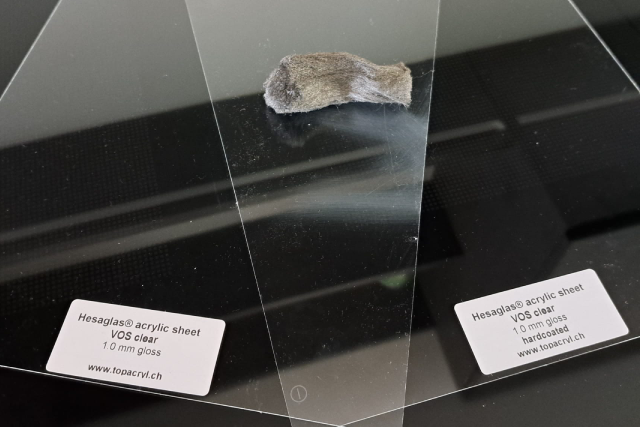

59 thicknesses

We manufacture any thickness from 0.3 mm to 8.0 mm in 0.1 mm increments. Each individual panel is measured at five points and we guarantee a tolerance of

+/-0.2 mm over the whole sheet. For special applications we can also work with tolerances of +/- 0.1 mm, where the panels are measured at 15 points.

4 different surfaces

The standard glossy surface is characterised by excellent optical properties. But we also produce three different matt surfaces (extra light matt, light matt, strong matt). Because these structures are reproduced in the casting process, the reproducibility is perfect (in contrast to sprayed satin finishes).

3 degrees of cross linking

Our standard material VOS is not cross-linked and behaves like a normal acrylic glass. The HL and HT types, however, are cross-linked (HL light, HT strong). The chemical process of cross-linking gives the sheets better thermal and chemical resistance.

filters

UV: UV-C (no transmission, UV-B 280 - 315 nm and UV-A 315-380 nm)

VIS: 380 - 780 nm

NIR: NIR-A 780-1400 nm

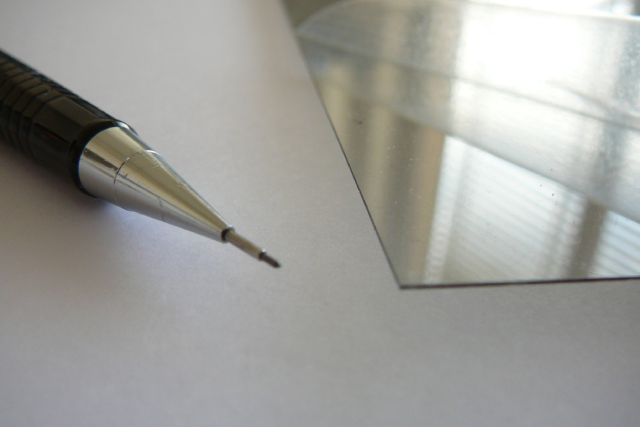

laser cutting

Hesaglas is excellent for laser cutting. The narrow thickness tolerances help with cutting and engraving.

We are also happy to produce prototypes for you.

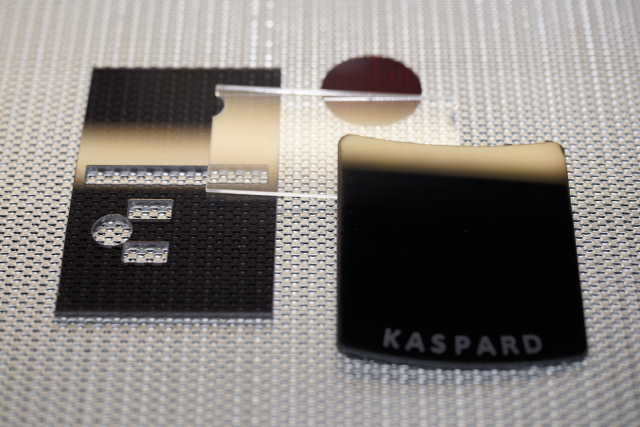

hardcoating

A thermally cured polysiloxane coating can significantly increase the surface hardness. This also improves the chemical resistance.